Content source: Energy storage box

On the electrochemical energy storage track, lithium-ion energy storage is currently relatively mature in technology and has the fastest development momentum. Among them, lithium-ion battery battery PACK technology is an extremely important part. What exactly is a battery PACK? What does its complete production line look like? Let’s go to solidify these concepts!

01

What is a battery pack?

Lithium-ion battery PACK, also known as battery module, is a lithium-ion battery manufacturing process that refers to connecting multiple lithium-ion single cell groups in parallel and series, taking into account the system mechanical strength, thermal management, and BMS. Matching issues. Its important technologies are reflected in the overall structural design, welding and processing process control, protection level, active thermal management system, etc. If two batteries are connected in series or parallel to form a specific shape according to customer requirements, it is called PACK.

The important components of the battery PACK include the five parts of the single battery module, electrical system, thermal management system, box, and BMS.

▷Battery module: If the battery PACK is compared to a human body, then the module is the "heart", responsible for the storage and release of electrical energy.

▷Electrical system: It is mainly composed of connecting copper strips, high-voltage wire harnesses, low-voltage wire harnesses, and electrical guarantee devices. The high-voltage wire harness can be regarded as the "artery blood vessel" of the battery PACK, which continuously delivers battery power to the end load. The low-voltage wire harness can be regarded as the "neural network" of the battery PACK, transmitting detection signals and control signals in real time.

▷Thermal management system: The thermal management system mainly has two methods: air cooling and liquid cooling, and liquid cooling can be divided into cold plate liquid cooling and immersion liquid cooling. The thermal management system is equivalent to installing an air conditioner on the battery PACK. The battery will generate heat in discharge mode. To ensure that the battery operates at a reasonable ambient temperature and improve the battery cycle life, the system temperature difference is generally required to be ≤5°C.

▷Box: Mainly composed of box, box cover, metal bracket, panel and fixing screws, it can be regarded as the "skeleton" of the battery PACK, playing the role of support, resistance to mechanical impact, mechanical vibration and environmental protection.

▷BMS: The abbreviation of "Battery management system", that is, the battery management system, can be likened to the "brain" of the battery. It is mainly responsible for measuring parameters such as voltage, current and temperature of the battery, as well as balancing and other functions. Data can be transferred to MES.

▷ PACK lithium battery pack requires the battery to have a high degree of consistency (capacity, internal resistance, voltage, discharge curve, life);

▷ The cycle life of the battery pack PACK is lower than the cycle life of a single battery;

▷ Use under limited conditions (including charging and discharging current, charging method, temperature, etc.);

▷ After the lithium battery pack is formed, the battery voltage and capacity are greatly improved, and must be protected and monitored for charge equalization, temperature, voltage and over current;

▷ The battery PACK must meet the voltage and capacity requirements required by the design.

▷ Series and parallel composition: The battery module is composed of single cells connected in parallel and in series. Parallel connection increases the capacity, but the voltage remains unchanged. After series connection, the voltage doubles, but the capacity remains unchanged.

For example: 15 batteries with a voltage of 3.2 V connected in series are 48 V, which is a series boost;

For example, if two batteries with a capacity of 50 Ah are connected in parallel, the capacity will be 100 Ah, which is parallel expansion.

▷ Battery core requirements: Select the corresponding battery core according to your own design requirements. Batteries connected in parallel and in series must be of the same type and model, and the difference in capacity, internal resistance, and voltage value should not be greater than 2%. Whether it is a soft packaging battery or a cylindrical battery, multiple string combinations are required.

▷ PACK process: Battery PACK is realized in two ways. One is through laser welding or ultrasonic welding or pulse welding. This is a commonly used welding method. The advantage is that it has better reliability but is not easy to replace. The second is contact through elastic metal sheets. The advantage is that no welding is required and the battery is easy to replace. The disadvantage is that it may lead to poor contact.

Considering the production yield, efficiency and internal resistance of the connection points, laser welding is currently the first choice for many battery manufacturers.

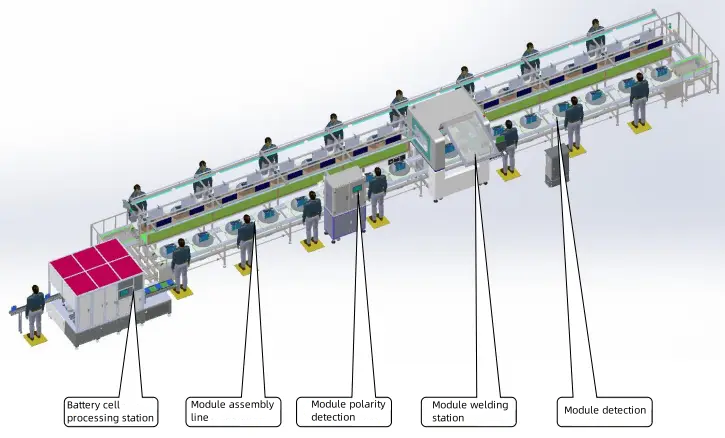

The lithium battery pack production line refers to a series of system collections of equipment and processes required to produce lithium battery packs.

It usually includes six core links: battery manufacturing, battery testing, battery grading, battery assembly, packaging and quality inspection. Among these links, battery manufacturing and battery assembly are the most core, and they directly affect the lithium battery pack. performance and quality.

▷ Battery cell manufacturing: It is the first step in the production line and can be divided into preparation of positive and negative electrode materials, battery core molding, battery core liquid injection and battery core maturation.

Battery core forming is the most critical step. There are methods such as winding forming, lamination forming and stamping forming, which determine the shape and size of the battery core and directly affect the performance and life of the battery core.

Different molding methods are suitable for different lithium battery products, depending on the situation.

▷ Battery cell testing: This process is mainly to screen out the batteries with unqualified quality to ensure the smooth progress of subsequent production links. It mainly includes battery cell capacity test, battery core internal resistance test and battery core temperature test. These test items can help manufacturers understand the performance of battery cells, detect problems in time, and make adjustments and optimizations.

Analysis on the future prospects of lithium battery pack

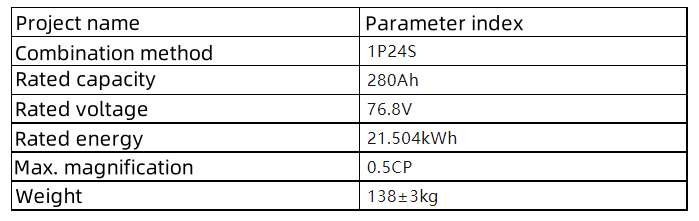

How to understand the technical parameters of battery PACK?

Take the above parameters as an example

▷ Combination method: 1P24S

S represents series cells, P represents parallel cells, 1P24S means: 24 series and 1 parallel. After series connection, the voltage is doubled, and the rated voltage is 3.2*24=76.8V.

▷ Rated capacity: 280Ah

The rated capacity of the battery refers to the capacity of the battery that can continue to work for a long time under rated working conditions. The rated capacity C of the battery, in ampere-hour (Ah), is the product of the discharge current (A) and the discharge time (h). Therefore, 280Ah means discharging at a maximum rate of 0.5C and lasting for 2 hours.

▷ Rated energy: 21.504kWh

Rated energy (Wh) = nominal capacity (Ah) * nominal voltage (V), which also means that the total energy released by a battery is related to both capacity and voltage.

Reprinted from 3060